Chemical Processing

STAINLESS STEEL CONDUIT & FITTINGS FOR CHEMICAL PROCESSING PLANTS

Plants that manufacture chemicals such as the following:

- Sulfuric Acid

- Nitric Acid

- Organic Acids

- Hydrogen Chloride

- Hydrochloric Acid

- Hydrogen Fluoride

- Hydrofluoric Acid

- Chlorine

- Alkalis and Hypochlorite

- Ammonia

Corrosive Agents

In chemical processing facilities, the major corrosive agents are the chemicals that are being processed. The manufacturing of chemicals can include processes such as separation, mixing, cooling and heating. Separation can further be subdivided to include processes such as extraction, filtration, settling, distillation, precipitation, drying and many others.

Some of the most common chemicals produced are nitric acid, ammonia, hydrogen chloride, sulfuric acid, and organic acids; however, these are just a few of the thousands that exist. At various stages in the chemical making process, chemicals may exist in different forms – from liquids to gases and vapors, all of which can cause harm to systems contained within the processing plant.

Aside from the chemicals themselves, steam and water are both corrosion catalysts that can be present in chemical plants. As steam condenses, it forms water, which can remain on surfaces. Impurities in steam and water can exist and may also introduce corrosion.

Temperature is also another factor to consider in chemical processing plants.

Other Factors

Reinstallation in these environments may be considered hazardous to installers given the amount of gases, fumes, and chemicals present.

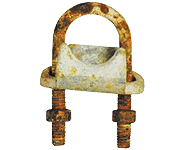

Stainless Steel Solutions

Stainless steel offers superior corrosion resistance compared to the formerly popular PVC-coated, zinc-plated, galvanized, and carbon steels — materials that have low initial overhead expenses but costly maintenance and replacement fees. The long service life of stainless steel — 10-20 times longer than carbon steel or iron in the same working environment — makes it the best overall choice to defend against the harmful effects of corrosion.

Note: Results after 4-week salt spray test.

Additionally, austenitic grades (Type 304 and Type 316 SS) have stable crystalline structures that result in good mechanical properties, including strength and ductility, at both high and low temperature extremes.

Not only does stainless steel offer corrosion resistance and durability, it has an aesthetic appeal of a bright polished finish and benefits the environment as it is able to be re-melted and reused, making it recyclable.

The success of your application can hinge on material selection. Gibson Stainless manufactures stainless steel products that address corrosion challenges while offering easy installation and minimal maintenance and repair.

To learn more about our stainless steel selection, visit our catalog or contact us today.