Coastal & Marine

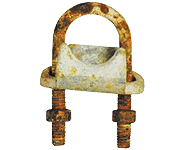

STAINLESS STEEL CONDUIT & FITTINGS FOR COASTAL & MARINE

- Offshore Oil Platforms

- Coastal and Shoreline Structures

- Docks and Piers

Corrosive Agents

Ocean water accounts for about 97% of the Earth’s water supply and can be one of the most corrosive compounds to which a metal may be exposed.

The major and minor constituents of seawater are what give it its corrosive nature. The most abundant ions found in seawater include chloride (CL-), sodium (Na+), magnesium (Mg2+), sulfate (SO24-), calcium (CA2+), and potassium (K+). The amount of these ions can vary as evaporation and rainfall cause different concentrations; however, the total salt content in ocean water typically ranges from 32% to 36%.

In addition to the above abundant ions, elements such as dissolved gases (e.g., carbon dioxide and oxygen), organic materials, and microscopic organisms are also a part of seawater. These elements can vary by tidal cycle, season, and especially by location.

Metals that come in direct contact with saltwater are at risk; however, so are metals that are simply present in saltwater atmospheres. Locations within five to ten miles of saltwater are at risk for corrosion as sea salt can be carried by weather (wind, fog, and rain). In addition to sea salt, airborne contaminants (e.g., nitrogen oxides, chlorides, sulfur dioxide, etc.), wind, moisture, and temperature can all be instigators of corrosion. Wind and moisture are usually elevated in coastal environments and can cause a metal to corrode up to ten times faster than air with normal humidity levels.

Other Factors

In addition to corrosive agents, other factors to consider in coastal & marine environments are the dangers and cost of reinstallation. The transportation of materials to offshore project sites, as well as difficult-to-access areas and ocean tides can all pose challenges. Specialized installers may even be required in such applications. Structures such as docks and piers may present a need for an aesthetic appeal as well.

Stainless Steel Solutions

Stainless steel offers superior corrosion resistance compared to the formerly popular PVC-coated, zinc-plated, galvanized, and carbon steels — materials that have low initial overhead expenses but costly maintenance and replacement fees. The long service life of stainless steel — 10-20 times longer than carbon steel or iron in the same working environment — makes it the best overall choice to defend against the harmful effects of corrosion.

Note: Results after 4-week salt spray test.

Additionally, austenitic grades (Type 304 and Type 316 SS) have stable crystalline structures that result in good mechanical properties, including strength and ductility, at both high and low temperature extremes.

Not only does stainless steel offer corrosion resistance and durability, it has an aesthetic appeal of a bright polished finish and benefits the environment as it is able to be re-melted and reused, making it recyclable.

The success of your application can hinge on material selection. Gibson Stainless manufactures stainless steel products that address corrosion challenges while offering easy installation and minimal maintenance and repair.

To learn more about our stainless steel selection, visit our catalog or contact us today.