Infrastructure

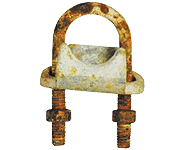

STAINLESS STEEL CONDUIT & FITTINGS FOR INFRASTRUCTURE

- Tunnels

- Bridges

- Airports

- Construction

- Industrial Buildings

- Transportation (Subways, Rail Systems)

Corrosive Agents

Infrastructure can be found all around us from tunnels and bridges to buildings and architecture. Forms of infrastructure are most often exposed to weather and other elements that can cause corrosion. Water takes on many forms – rain, ice, sleet, snow – and can be corrosive to metals, especially when the metals are exposed for long periods of time. An even greater corrosive element is acid rain. When coal and other fossil fuels are burned, emissions such as sulfur dioxide and nitrogen oxide are released, causing pollutants in the air. When these pollutants in the air combine with atmospheric water, acid rain is formed.

Structures such as tunnels and bridges are also exposed to road salts and deicing liquids that combat winter conditions. Road salts are composed of sodium and chloride ions. Other elements such as ferrocyanide and impurities can be present and lead to further corrosion.

Other Factors

In addition to corrosive agents, there are other considerations to keep in mind when choosing materials for infrastructure. Fire resistance is often important. The ability to withstand vibration and shock in high traffic areas (bridges), as well as the need for overall strength and high load capacity, are important. Environmental concerns and an aesthetic appeal are often factors as well. Consideration should also be given to reinstallation where dangers exist for workers and where shutdowns in roads or bridges may be costly and cause delays.

Stainless Steel Solutions

Stainless steel offers superior corrosion resistance compared to the formerly popular PVC-coated, zinc-plated, galvanized, and carbon steels — materials that have low initial overhead expenses but costly maintenance and replacement fees. The long service life of stainless steel — 10-20 times longer than carbon steel or iron in the same working environment — makes it the best overall choice to defend against the harmful effects of corrosion.

Note: Results after 4-week salt spray test.

Additionally, austenitic grades (Type 304 and Type 316 SS) have stable crystalline structures that result in good mechanical properties, including strength and ductility, at both high and low temperature extremes.

Not only does stainless steel offer corrosion resistance and durability, it has an aesthetic appeal of a bright polished finish and benefits the environment as it is able to be re-melted and reused, making it recyclable.

The success of your application can hinge on material selection. Gibson Stainless manufactures stainless steel products that address corrosion challenges while offering easy installation and minimal maintenance and repair.

To learn more about our stainless steel selection, visit our catalog or contact us today.