Wastewater

Treatment

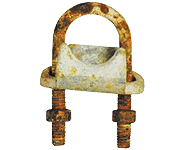

STAINLESS STEEL CONDUIT & FITTINGS FOR WASTEWATER TREATMENT

Corrosive Agents

Wastewater, which can include sewage as well as water polluted by industrial production, is treated in wastewater treatment plants where biological, physical, and chemical processes take place.

Pre-treatment and primary treatment mostly involve physical processes where solids are removed and pumped away for more treatment. Secondary treatment involves biological processes, where corrosive agents are first introduced. In secondary treatment, air is added to help bacteria and protozoa consume soluble organic contaminants. Further solid separation is also performed in this step. Finally, tertiary treatment ensures that water has a high enough quality to be discharged into the environment (oceans, lakes, rivers, etc.). Parts of the tertiary treatment process can include filtration, carbon absorption, further settlement in lagoons, nutrient removal (such as nitrogen and phosphorous) and more. Carbon adsorption removes toxins by filtering the water over activated carbon. Nitrogen removal is done by a process called denitrification in which nitrate is reduced to nitrogen gas, and phosphorous removal often involves the addition of salts or iron, aluminum or lime. All of these processes involve the addition, or the release, of elements that can be corrosive.

The disinfection process, sometimes known as “effluent polishing,” is one of the last steps in the treatment of wastewater and typically includes the use of oxidizing agents such as chlorine and ozone, which also can be corrosive in nature.

Often times, other chemicals such as ferric chloride and ferrous sulphate may also be used in the process of wastewater treatment.

In addition to the corrosive fumes that may be present during wastewater treatment, a very wet atmosphere in the plant increases the risk of corrosion.

Other Factors

Many regulations, such as the Clean Water Act, surround wastewater treatment plants as it is necessary to minimize pollution and produce quality water, free of pollutants, especially when the water is being released into the environment or is being treated for drinking purposes. As such, strict cleaning and chemical treatment may be required in wastewater treatment plants, introducing additional corrosive agents. Metal leaching also needs to be prevented to protect water quality.

Stainless Steel Solutions

Stainless steel offers superior corrosion resistance compared to the formerly popular PVC-coated, zinc-plated, galvanized, and carbon steels — materials that have low initial overhead expenses but costly maintenance and replacement fees. The long service life of stainless steel — 10-20 times longer than carbon steel or iron in the same working environment — makes it the best overall choice to defend against the harmful effects of corrosion.

Note: Results after 4-week salt spray test.

Additionally, austenitic grades (Type 304 and Type 316 SS) have stable crystalline structures that result in good mechanical properties, including strength and ductility, at both high and low temperature extremes.

Not only does stainless steel offer corrosion resistance and durability, it has an aesthetic appeal of a bright polished finish and benefits the environment as it is able to be re-melted and reused, making it recyclable.

The success of your application can hinge on material selection. Gibson Stainless manufactures stainless steel products that address corrosion challenges while offering easy installation and minimal maintenance and repair.

To learn more about our stainless steel selection, visit our catalog or contact us today.