It is often a misconception that working with stainless steel conduit in the field is difficult and that specialized threaders and benders need to be used.This, however, is not the case. Stainless steel can be installed using common field tools; no specialized tools or processes are necessary, saving time, labor, and costs. A few precautions should be observed with stainless steel, but working with stainless steel rigid conduit (RMC) is similar to working with galvanized rigid conduit (GRC).

A stainless steel rigid conduit system is often the choice in industrial and corrosive environments as it has a greater wall thickness than IMC or EMT. A rigid conduit system is installed using threaded connections, which provide electrically continuous joints, while also allowing for easy installation and a robust system.

To ensure rigid conduit performs as expected, it is important to install it in accordance with all relevant National Electric Code (NEC) guidelines. Additionally, when making field alterations to address unique installation challenges, it is always best practice to review NFPA 70 (National Electric Code®) and consult local experts, including your AHJ (Authority Having Jurisdiction), to ensure a safe, effective, and long-lasting conduit system.

To help with pre-installation alterations such as cutting, threading, and bending, we have put together a resource: Cutting, Threading and Bending Instructions for Stainless Rigid Conduit. In it you will find instructions as well as best practices that are specific to the processing of stainless steel RMC. Care must be taken when performing these pre-installation alterations as failure to do so properly can make installation more difficult, time-consuming, or costly and could impact the lifespan of the conduit system.

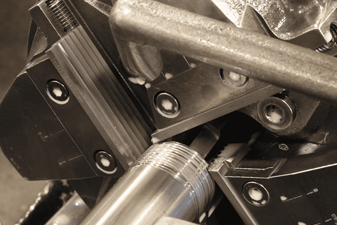

When cutting, threading, and bending stainless steel conduit, all equipment that comes into contact with the conduit, including bending shoes and vises, should be new or used exclusively on stainless steel. Using equipment that has processed ferrous material will impregnate the surface of the stainless steel with free iron, leading to rust and corrosion.

In addition to being installed with standard tools, stainless steel conduit can be installed by skilled industrial electricians without the need for labor-intensive procedures like sealing, sprays, paint, or surface treatments. This lessens the maintenance burden on facility owners and operators, reducing periodic inspections and upkeep costs. A proper installation of stainless steel rigid conduit can last the lifetime of the facility, even in environments where corrosion is a concern.