Understanding Thread Types

Electrical conduit provides a means of protection for wiring and cable in electrical systems. Furthermore, rigid (heavywall) conduit is designed to act as a path to ground, and therefore must always be able to carry current. A rigid conduit system is installed using threaded connections, which provide electrically continuous joints, while also allowing for easy installation.

UL 6A and 514B both require a pipe thread that conforms with the requirements in ASME B1.20.1, the national standard for pipe threads. This standard includes two of the most common types of threads found in electrical fittings in a rigid conduit system: National Standard Pipe Tapered (NPT) and National Standard Pipe Straight (NPS).

(There are other threads types employed by electrical manufacturers; however, this blog will cover NPT and NPS, which are the most common in rigid conduit systems and can sometimes cause confusion.)

NPT AND NPS

Thread types for a given product are selected during the design process based on several factors including design intent, industry convention, and UL regulation.

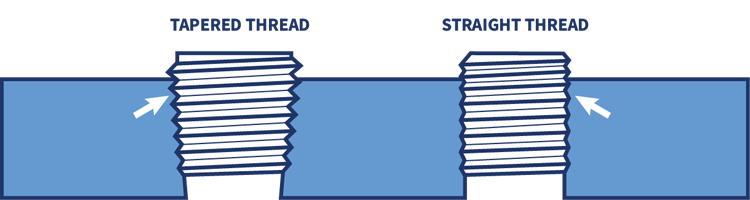

NPT and NPS threads are similar in that they have the same angle between the flanks of the thread (60 degrees), shape (truncated peaks and valleys), and pitches (threads per inch). However, as seen in Image A, NPT threads are tapered whereas NPS threads are straight (parallel.)

When mated, that is NPT-to-NPT, tapered threads compress against each other to form a close, tight seal when torqued, and will not loosen due to vibrations. NPT threads are often found on conduit, nipples, elbows, and fittings. The taper rate for all NPT threads is ¾-inch per foot or 1 inch per 16 inches of length.

NPS threads, when mated together or when mated with male NPT threads, provide a secure, electrically continuous connection that is not sealed, by design, to allow unwanted substances (e.g., condensation, hot gases) to work their way out of the raceway. If a sealed connection is desired at an NPS threaded joint, care must be taken to avoid electrically insulating the joint through the use of non-conductive thread sealants, which would interrupt the path to ground.

IMAGE A

Rigid Conduit Threaded Connections

UL Listed rigid conduit has a tapered male thread and UL Listed rigid couplings have a straight female thread. This connection between a tapered (NPT) and straight (NPS) thread is by design and allows for any accumulated condensation within the raceway to drain.

This connection also serves a purpose in hazardous locations. (NEC) Article 500.8E requires threaded rigid conduit to be “wrench-tight” and have five threads fully engaged to help ensure the explosion-proof integrity of the rigid stainless conduit system. In the event of an explosion within the raceway, the joint design between tapered and straight threads enables hot, expanding gases to cool as they exit the raceway before discharging into the surrounding atmosphere.

Gibson Stainless’s threaded rigid conduit and fittings can be found on the Products page. Please contact us for specific questions on the thread type of a certain product.

Print This Page

Print This Page Email This Page

Email This Page